Industrial Metal Enclosure

1. Material selection: Considering both strength and environmental adaptability

Stainless steel (304/316): resistant to acid and alkali corrosion, suitable for high-corrosion scenarios such as chemical, marine, and food processing. 316 stainless steel has stronger resistance to chloride ion corrosion.

Aluminum alloy (6061/5052): lightweight (density is about 1/3 of stainless steel), excellent thermal conductivity, suitable for electronic equipment that needs heat dissipation (such as inverters, controllers), and the surface can be anodized to enhance weather resistance.

Carbon steel (Q235/SPCC): high strength, low cost, often powder spraying or galvanizing to improve rust resistance, suitable for heavy industrial scenarios with high mechanical protection requirements.

2. Protection level: Environmental adaptability under international standards

IP level (IEC 60529):

IP65: Dustproof (completely sealed) + low-pressure water spray (nozzle sprays water from any direction without damage), suitable for outdoor equipment (such as charging piles, monitoring equipment).

IP66: High-pressure water washing (such as fire hose spray), suitable for industrial washing areas (food factories, sewage treatment).

IP67/IP68: Short-term immersion/long-term underwater environment (such as submarine sensors, diving equipment).

3. Structural design: functionality and installation convenience

Modular design: supports splicing and expansion (such as rail installation and detachable side panels), which is convenient for equipment upgrade and maintenance.

Cooling solution: built-in cooling fins, ventilation holes (with dustproof nets), heat pipe cooling or fan guide structure to solve the overheating problem of high-density electronic components.

Electromagnetic shielding (EMI/RFI): through conductive coating, metal lap strips or sealing gaskets, electromagnetic interference is blocked to ensure signal stability (such as communication base stations, medical equipment).

Sealing system: silicone rubber sealing rings, snap-on locks or stainless steel hinges are used to ensure sealing during long-term use.

Size & Capacity

Dimensions:

Small: 100x100x80mm (ideal for single switches or small controllers).

Medium: 300x400x200mm (accommodates multiple DIN rail devices, circuit breakers).

Large: 600x800x300mm (for industrial PLCs, power distribution units).

About Us

why choose us?

We are a well-known enterprise in China specializing in the production of various distribution boxes, and we focus on distribution boxes. Our product range includes: metal wall-mounted distribution boxes, top stainless steel distribution boxes, floor-standing cabinets, modular cabinets, network cabinets, terminal boxes, junction boxes, sealed boxes, telephone boxes, etc.

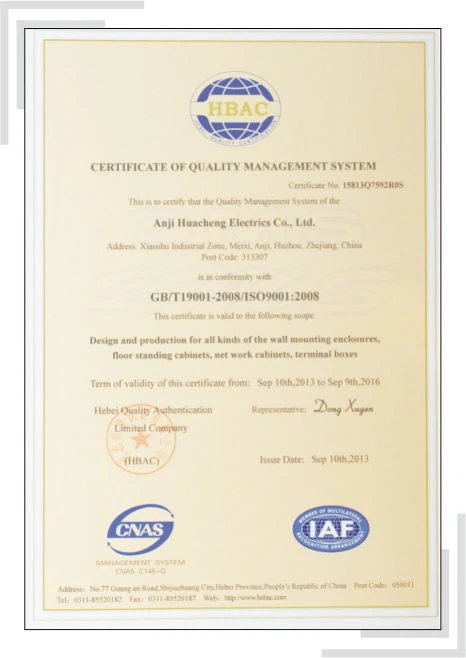

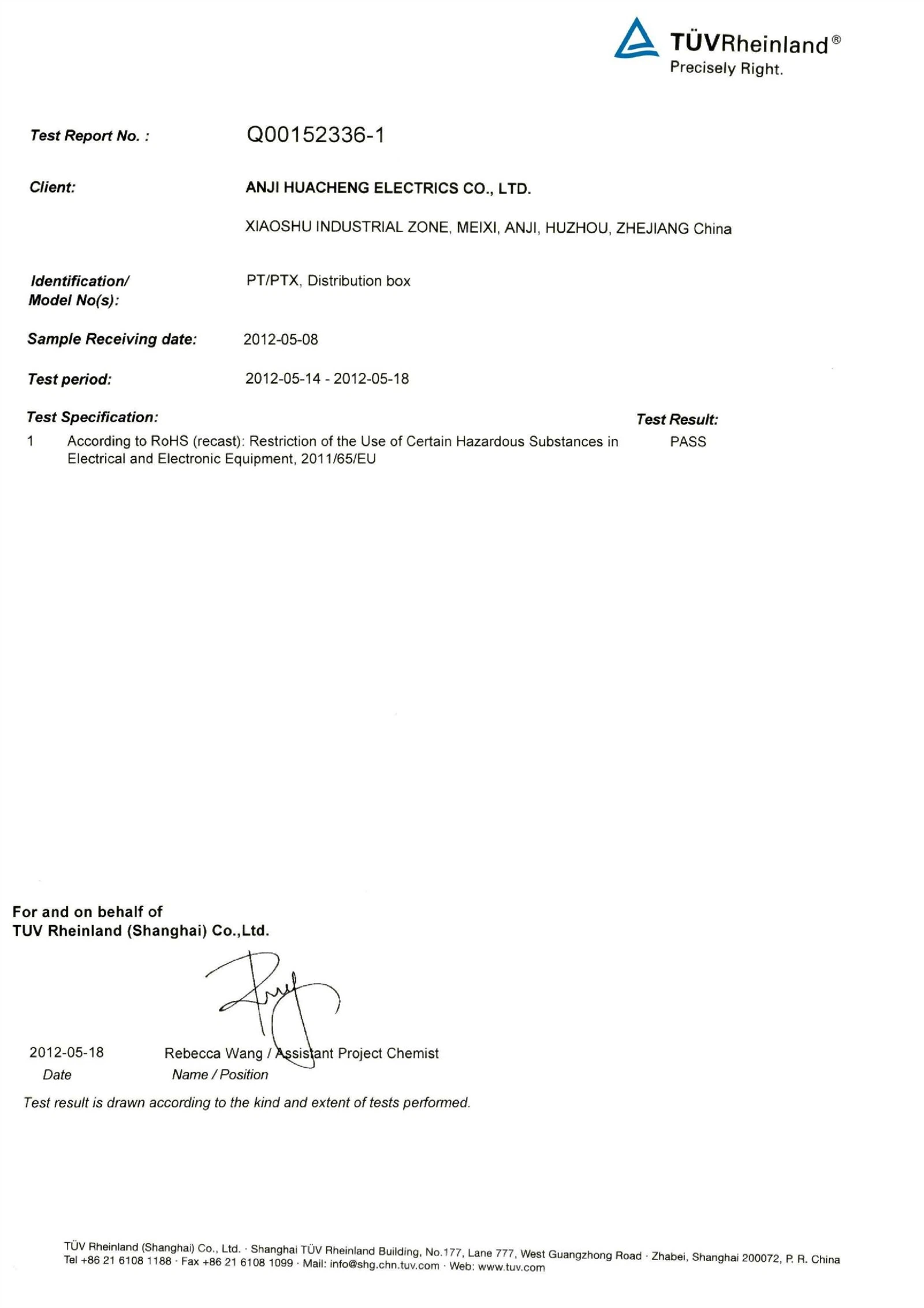

Our Certificates

FAQ:

Which industrial scenarios are IP66 and NEMA 4X protection levels applicable to?

IP66 (IEC standard): dustproof (level 6) + high-pressure water washing (level 6, can withstand water jets from 12.5mm nozzles from any direction), suitable for scenarios that require frequent washing (such as food processing plant equipment, sewage treatment pump control boxes), outdoor equipment (such as outdoor LED display housings).

NEMA 4X (US standard): waterproof, dustproof, corrosion-resistant, focusing on material corrosion resistance (such as stainless steel), commonly found in chemical workshops (resistance to acid and alkali gases), coastal industrial facilities (anti-salt spray erosion), while meeting IP66 equivalent protection performance, but more emphasis on the corrosion resistance certification of the material itself (such as 316 stainless steel).

Hot Tags: industrial metal enclosure, China, manufacturers, suppliers, factory, customized, wholesale, IP66 Wall Mount Distribution Box, PTI W T Inner Door Enclosure, Steel Electrical Termianl Box, IP66 Waterproof Electrical Distribution Box, Double Door Wall Mount Enclosure, Wm Enclosure

You Might Also Like

Send Inquiry